The research which has been undertaken has been supported by the following industrial partners and sponsors.

|

| Noise generated by traffic, industrial and recreational activities is one of the main local environmental problems in Europe. Although the noise generated by individual cars has been reduced by 85 percent (8 dbA) since 1970, this achievement has been negated through the growth in the number of cars on the roads and the longer distances travelled. |

|

|

According to the UK Government surveys, the total amount of traffic using the roads has grown by 73 percent between 1980 and 2002, which measures the total distance travelled by vehicles using pneumatic tyres, from 277 to 478 billion kilometres. UK Government forecasts for the future growth are around 17 percent for the period 2000 to 2010. |

| UK Government surveys have found that 30 percent of people questioned were classed as being adversely affected by the impact of road traffic noise, with the main types of activity disturbed being the ability to sleep, watching the television or listening to the radio and not being able to have doors or windows open. The main reactions were classed as irritation and anger, with some people reporting depression or even having to temporarily leave their houses. The Building Research Establishment Survey reported that road traffic noise is heard in 47 percent of residential houses with between one half and two thirds of those owners objecting to the noise. |

|

|

The sources of noise from a vehicle can be separated into four main areas, the engine, exhaust, air intake and the noise produced as a result of the tyres rolling in contact with the road. Reductions in the former sources have been significant and it is now recognised that the tyre / road interaction noise is dominant for constant speeds for almost all types of driving. It is also a significant contributor during acceleration and braking. |

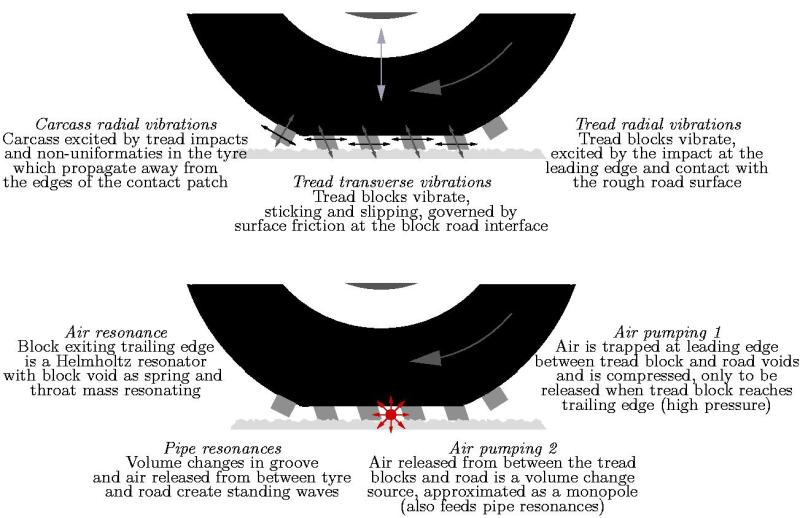

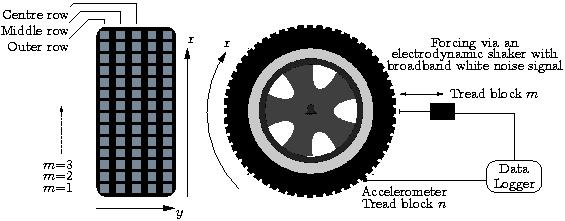

| The noise which is radiated from the tyre surface is produced by several mechanisms, including the vibration of the tyre surface, vibrations of the tread blocks and resonances of the air cavities in the contact patch between the tyre and the road surface. (Open in new window to read text) |

|

|

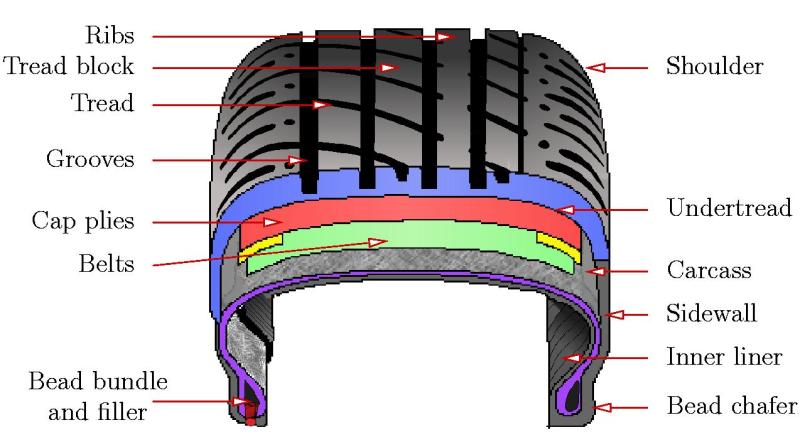

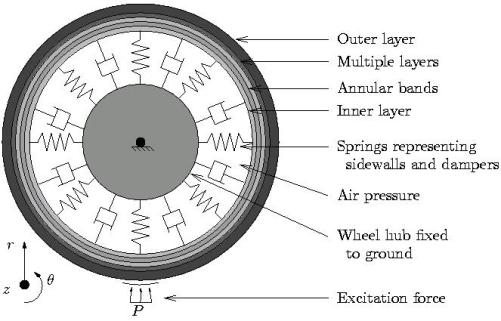

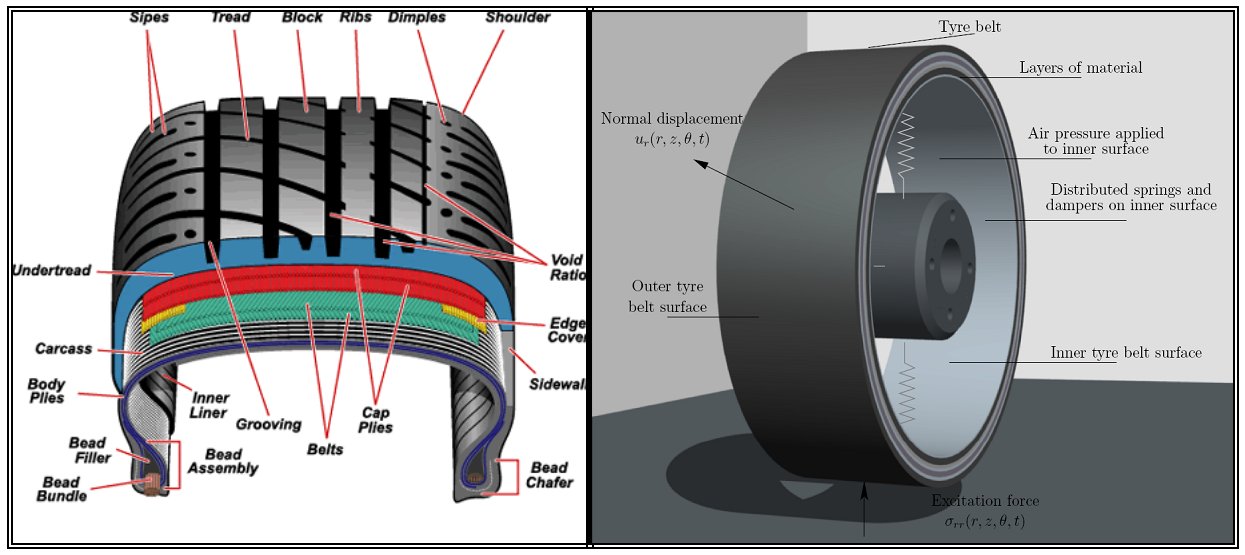

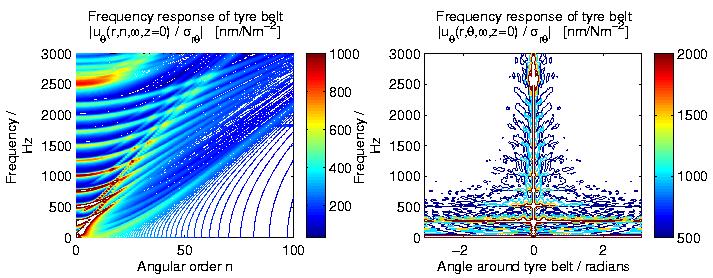

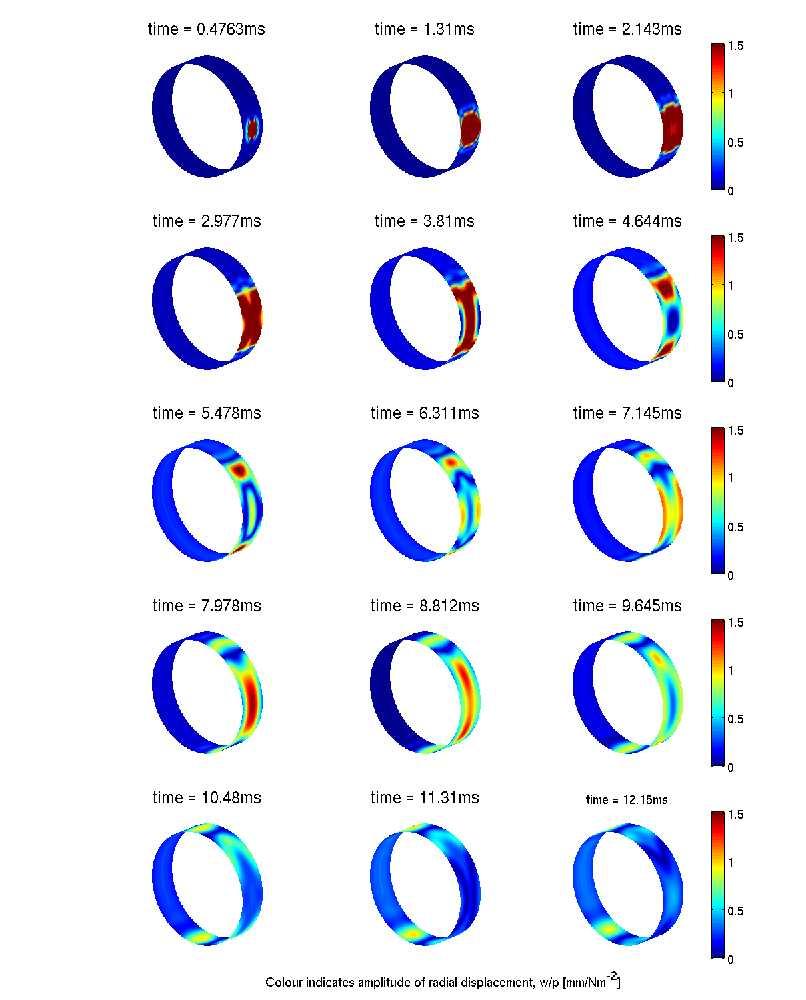

In order to investigate the noise produced by the tyre rolling over a rough surface, detailed information must be known about how it responds to excitation. A methodology for determining the vibration characteristics of the tyre belt has been successfully completed. This tyre belt, located between the sidewalls and made up of several different layers of materials, has been modelled as a three dimensional viscoelastic multilayer structure, including the curvature of the tyre surface, the significance of each individual material layer and its properties, for a wide range of excitation frequencies. |

|

|

| The displacement of the tyre surface has been determined for the case where a force is applied normal to the surface and tangential to the surface, using only design data. Spectral decompositions are used to identify mode shapes and resonances in the frequency domain rather than the time domain. |

|

| Other mathematical models have been used to determine the vibration of the tyre belt using simplifications to obtain shell and flat bending plate models. Deriving parameters for these models is usually done empirically with reference to data collected from experimental measurements, or estimations are made. Advantages of this method are that experiments can be performed on real tyres and parameters obtained without needing to know exact details of the construction of the tyre. However, for every potential tyre design to be investigated, a physical tyre must be made, at expense and time to the manufacturer. It also does not allow any detailed physical insight into the stress and displacement in each layer. |

|

| A method has been determined to find these simplified plate parameters by comparing the response from a simplified bending plate to the full three-dimensional viscoelastic tyre belt model, using a multivariable optimisation technique to minimise any differences, without requiring access to experimental data. These parameters are used in a finite width model of the tyre, which takes into account the effect of the sidewalls. Comparisons can then be made between this model and experimental data. |

|

|

| Once the response of the tyre surface is known for an applied load, the acceleration of the tyre surface can then be found as the tyre rolls over a rough road surface. Methodologies have been developed to find the far field sound pressure radiated from a tyre as it rolls over several different road surfaces, taking into account the amplification by the horn effect. This amplification comes from the geometry created as the tyre surface meets the road surface, in a shape analogous to a gramophone horn. |

|

| Some of this work was carried out under different grants at the University of Cambridge, including by Dan O'Boy as part of a Ph.D research programme. This research is being continued by Dan O'Boy and Loughborough University who have computational methods which can be used to determine the far field sound radiated by a tyre as it rolls over a rough road surface using only the design data of the tyre and road surface. Facilities and experience also exists to perform experiments to measure the sound amplification from the horn geometry on different road surfaces. Numerical methods including boundary element modelling is available to complement experimental measurements. |